Outstanding technology

XGas is a modern technology company transforming hydrogen production with its unique patented pyrolysis process. This method turns natural gas into turquoise hydrogen and solid carbon, providing an efficient and affordable alternative to conventional hydrogen production. XGas's scalable technology and focus on sustainability aim to address the growing need for clean hydrogen, significantly influencing the global energy market.

Turquoise hydrogen is made by methane pyrolysis, which converts natural gas into hydrogen and solid carbon without producing CO₂. This process is cost-effective and environmentally friendly. It avoids the carbon emissions linked to grey and blue hydrogen and creates solid nano carbon as a useful by-product for different industrial and possibly agricultural uses.

XGas's unique pyrolysis process is different from other turquoise hydrogen production methods. It has an efficiency of better than 99%, requires less than 9kWh of energy per kg of hydrogen, and does not need catalysts, resulting in high-purity carbon. Additionally, XGas plans to optimize the process for various advanced uses of carbon, such as lightweight, strong, and electrically conductive materials, as well as for agricultural food production.

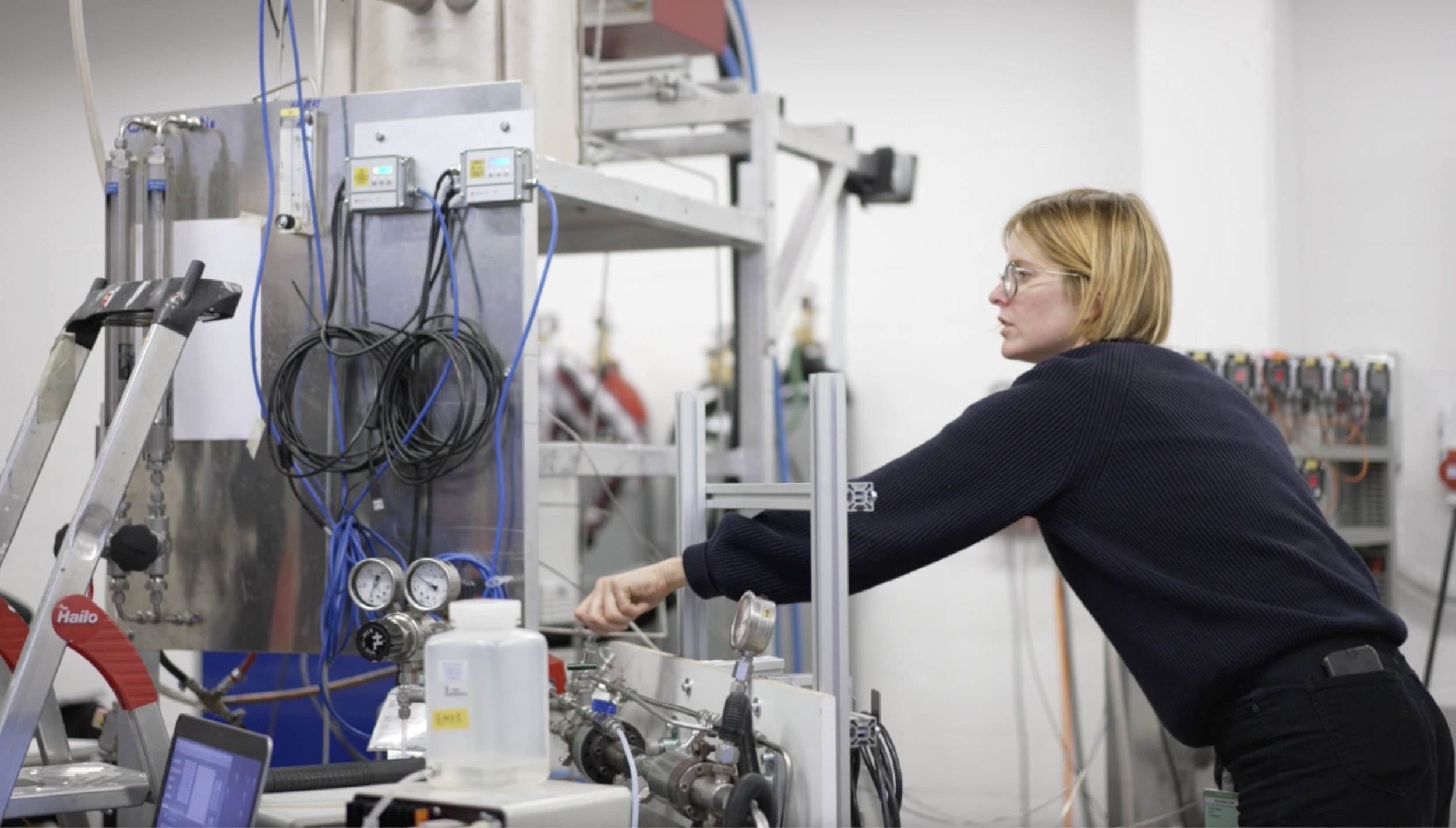

In 2018 XGas AS established a prototype in the laboratory in Switzerland, Plustherm Point AG, Birr. XGas AS daughter company, XGas Swiss GmbH, in Switzerland is set up to take care of development activities in Switzerland together with the partner Plustherm Point AG. Plustherm is providing the heating induction solution patented in XGas AS technology, by the Dehns UK registered patent attorneys. The patents is today validated in several countries; UK, EU, USA, Canada, Japan, Norway and Switzerland with the two first patent families and a third patent family under development.